In the world of hair extensions, quality, and reliability are paramount. Understanding the journey from the factory to the salon is essential for salon owners and hair extension retailers to appreciate the efforts that go into producing high-quality products. This article will provide a glimpse into the world of wholesale hair extension suppliers, including the hair-sourcing process, manufacturing, packaging, quality control, and shipping logistics.

The Hair Sourcing Process

Hair Collection

The journey of hair extensions begins with the collection of raw hair. Suppliers typically source hair from various countries, including China, India, Brazil, and Southeast Asia, where donors sell their hair at local temples or collection centers. The hair is then carefully sorted by length, color, and texture to ensure consistency in the final product.

Hair Processing and Manufacturing

Once the raw hair has been collected and sorted, it undergoes several processing steps:

- Cleaning and disinfecting: The hair is thoroughly cleaned to remove dirt, oils, and other impurities.

- Untangling and aligning: Hair strands are meticulously aligned in the same direction to prevent tangling and ensure a natural look.

- Coloring and dyeing: Hair may be dyed to achieve various shades and colors, using gentle dyes to preserve the hair’s integrity.

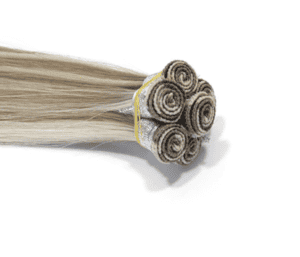

- Wefting and bonding: Hair strands are sewn or bonded onto wefts or other attachment methods, such as tape, clips, or keratin bonds.

- Quality inspection: The final products are carefully inspected to ensure they meet the supplier’s quality standards.

Packaging and Branding

After processing and manufacturing, hair extensions are packaged and branded to meet the specific requirements of each retailer. This may involve custom packaging design, logo printing, and the inclusion of care instructions or marketing materials. Suppliers work closely with retailers to ensure their branding needs are met and the final product reflects the desired image.

Quality Control

Throughout the entire process, from hair collection to packaging, quality control is a top priority for wholesale hair extension suppliers. Rigorous checks at each stage ensure that only the highest quality products reach the end consumer. Suppliers may also provide guarantees or warranties on their products, demonstrating their confidence in their quality standards.

Shipping and Logistics

Customs and Regulations

Once the hair extensions are ready for shipment, suppliers must navigate international customs and regulations. They must ensure all necessary documentation is in place, including proper packaging, labeling, and compliance with any import restrictions or requirements in the destination country.

Conclusion

The world of wholesale hair extension suppliers is a complex and intricate one, with numerous steps involved in bringing high-quality products from the factory to the salon. By understanding the journey that hair extensions undergo, salon owners and retailers can better appreciate the efforts of suppliers and make informed decisions when choosing chain and its various stages.