Machine weft, also known as fusion or tape-in extensions, are becoming increasingly popular due to their precision and ease of use.

With machine weft, salon owners and online retailers alike can provide clients with thicker, fuller hair that looks naturally beautiful – no more worrying about bulky wefts or messy applications.

This advanced technology has revolutionized the hair extension industry and is now the go-to choice for businesses looking to provide professional results without compromising on quality.

By investing in machine weft technology, you can offer your customers a seamless experience from

The purpose of this article is to discuss the advantages of machine-weft hair extensions and how they are revolutionizing the hair care industry.

What are Machine-Weft Hair Extensions?

Machine weft hair extensions are a popular type of hair extension that is created using advanced machinery and technology.

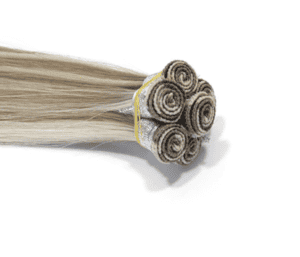

Unlike hand-tied extensions, machine wefts are produced by sewing or stitching hair strands together using a precise and automated process.

This results in a sturdy and consistent weft that offers numerous benefits for hair businesses, salon owners, and online retailers.

The production process involves feeding the hair strands into a specialized machine that sews them together along the top, creating a fine, continuous weft. This method ensures uniform thickness and length throughout the weft, making it easier to work with during installation.

Machine weft extensions are known for their superior quality, as they undergo rigorous quality control measures to ensure durability, minimal shedding, and reduced thread tangling.

Additionally, machine weft technology allows for increased production speed and efficiency, enabling manufacturers to meet the demands of high-volume orders.

With a wide range of hair types, textures, and colors available, machine weft extensions offer versatility and customization options to cater to the specific needs and preferences of salons, brands, and retailers.

By combining precision, consistency, and durability, machine weft hair extensions have become a game-changer in the hair extension industry, providing a reliable and high-quality solution for those seeking natural-looking and long-lasting hair extensions.

Difference between Machine Wefts vs. Hand Tied Hair Extensions

Machine weft hair extensions and hand-tied hair extensions are two popular methods used in the hair extension industry, each with its own unique characteristics.

Machine weft extensions are created using advanced machinery and technology, where hair strands are sewn or stitched together in a precise and automated process. This results in a consistent weft with uniform thickness and length, offering ease of installation and a seamless blend with natural hair.

On the other hand, hand-tied weft extensions are meticulously crafted by skilled artisans who manually tie individual strands onto a weft using a hand-knotting technique.

This process allows for greater flexibility and a more natural movement as the extensions mimic the way natural hair flows. Hand-tied extensions are known for their lightweight feel and versatility in creating different hairstyles.

In terms of quality and durability, machine weft extensions have an advantage. The precise production process ensures that the weft is sturdy, reducing shedding and tangling.

The uniform construction also provides consistency in thickness and length, resulting in a more polished and professional finish. Hand-tied wefts, while offering natural movement, may have variations in thickness and length due to the manual nature of the process.

When it comes to installation time, machine weft extensions are generally quicker to apply. The consistent weft allows for faster attachment and blending, making them ideal for time-sensitive situations such as salon appointments.

Hand-tied extensions, with their individually tied strands, require more time and expertise for proper installation, making them a preferred choice for those seeking a custom and tailored approach.

Additionally, machine weft extensions are suitable for high-volume orders due to their efficient production process, making them more readily available for salon owners and online retailers. Hand-tied extensions, on the other hand, are often handcrafted in smaller quantities, resulting in limited availability and potentially higher costs.

Ultimately, the choice between machine weft and hand-tied hair extensions depends on individual preferences and specific requirements. Machine weft extensions offer consistency, durability, and efficiency, while hand-tied extensions provide natural movement and a personalized touch.

It's essential to consider factors such as desired hairstyle, installation time, budget, and the overall look and feel desired when deciding between these two methods of hair extensions.

Quality and Consistency: The Key Benefits of Machine Weft

The consistent thickness and length throughout the weft are the key benefits of machine weft extensions, making them popular amongst salon owners and online retailers alike.

The precise production process ensures uniformity in every strand, creating a seamless blend within natural hair for a flawless look and feel.

The superior quality of the machine weft also adds to its durability. With the thick, sturdy construction, there is less shedding and tangling, making them long-lasting and low-maintenance.

The precision engineering of machine wefts also makes it faster to apply during installation.

The consistent weft makes it easier for salon professionals and stylists to quickly attach and blend the extensions into natural hair without compromising on quality or appearance of the natural look.

Machine weft hair extensions offer superior quality and consistency, making them the preferred choice for salon professionals and online retailers.

The precise production process ensures uniformity in every strand, creating a seamless blend within natural hair for a flawless look and feel. Additionally, machine weft extensions are known for their durability due to their sturdy construction which results in reduced shedding and tangling – allowing users to enjoy long-lasting hairstyles with minimal maintenance.

Speed and Efficiency: Streamlining Hair Extension Manufacturing

Machine weft technology is revolutionizing the hair extension industry with its precise production process and increased production speed.

This advanced method of weaving hair extensions offers uniformity in thickness, length, and texture for a more polished and professional finish.

Not only does it reduce time during installation, but it also allows for high-volume orders due to its efficient manufacturing process.

As a result, machine weft extensions are becoming increasingly popular among salon owners and online retailers looking for quality products that can be produced quickly at an affordable price point.

The efficient production process associated with machine weft extensions has a significant impact on cost and delivery time.

By streamlining the manufacturing process, salon owners and online retailers are able to purchase high-quality hair extensions at more affordable prices. Machine wefts also enable faster production times, ensuring that orders can be filled quickly while maintaining the consistent quality of the product.

Versatility and Customization: Meeting Diverse Customer Needs

Range of hair types, textures, and colors available in machine weft extensions

This makes them a popular choice among salon owners and online retailers and other methods of hair extensions.

The versatility of machine weft extensions also allows for customization, giving customers the ability to create unique hairstyles that are tailored to their individual needs.

Whether looking for a sleek straight look or stunning curls, it’s easy to find the perfect match with machine weft extensions.

The increased variety of machine wefts also makes it easier for salon owners and online retailers to meet the needs of diverse customers, providing them with a range of options that can be tailored to their individual styles.

Customization options, such as lengths, weights, and packaging

The versatility and customization options of machine-weft hair extensions make them an ideal choice for salon owners, online retailers, and customers alike.

With the precise production process ensuring uniformity in every strand, they create a seamless blend within natural hair for a flawless look and feel.

The increased variety of machine wefts also provides a range of options that can be tailored to individual styles – from sleek straight looks to stunning curls.

Machine Weft Extensions and Sustainable Practices

Minimizing waste and optimizing resource utilization

Machine weft hair extensions offer an eco-friendly alternative to traditional methods of hair production.

Using this method not only saves time during installation but also promotes an ethical approach to hair extension manufacturing by sourcing human hair sustainably.

Promoting eco-friendly practices within the hair extension industry

The efficient production process reduces the amount of time required for each extension – resulting in faster order fulfillment times and decreased overhead costs.

Conclusion

Machine Weft Extensions offer a unique combination of efficiency, affordability, and sustainability that make them an ideal choice for salon owners, online retailers, and customers alike.

By leveraging the power of precision in hair extensions through machine wefts, businesses are able to provide high-quality products at more affordable prices while minimizing environmental impact.

Alvin Hair - Trusted Natural Hair Extensions Manufacturer

Alvin Hair is a well-known provider of various hair extensions such as hand-tied hair extensions, machine wefts, sew-in hair extensions, and more!

Our variety of hair extensions puts us in the spotlight as one of the professional and prominent names in the hair industry. We have years of experience delivering quality extensions to many clients at an affordable price!