As the market size for the hair extension industry continues to grow and evolve, manufacturers of hair extension products face an increasingly complex competitive landscape, filled with challenges and opportunities.

In our article, “The Future of Hair Extension Manufacturing: Predictions and Innovations,” we delve into the exciting world of the extension and market dynamics, emerging technologies and innovative practices that are set to redefine this dynamic sector.

This insightful piece is designed to provide valuable predictions detailed analysis, and insights for hair businesses, salon owners, and online retailers who are eager to stay ahead of the curve and thrive in this competitive market.

From groundbreaking materials and production techniques to sustainable practices and shifting consumer demands, this article will explore the transformative innovations shaping the future of hair extension manufacturing, making it an essential read for anyone looking to navigate the thrilling and ever-changing global hair extension industry.

Current State of Hair Extension Manufacturing

The hair extension industry is forecast period be a rapidly growing market, with the global hair extensions market estimated to reach $5.3 billion by 2027.

Hair extension manufacturers are faced with a number of challenges, including pricing, competition, supply chain disruptions, and increasing customer expectations. With the rise of social media, customers have become more informed and demanding when it comes to their hair products.

They expect high-quality products at competitive prices and are increasingly looking for sustainable and ethical options.

Key players in the industry include Alvin Hair, Perfect Locks LLC, and Private Label Extensions in the USA, Kingshow International in China, DreamCatchers suppliers & factories, Super Hair Factory, and Egbeauty Hair Co., Maad Extensions, and Hey Gorgeous You.

Recent technological advancements have enabled manufacturers to produce higher-quality hair extensions faster than ever before.

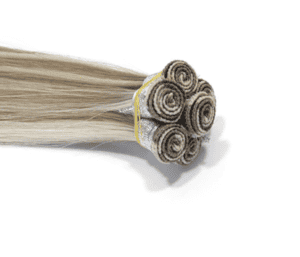

For example, processes such as ultrasonic wave cutting, heating welding, and sewing allow for the precision manufacturing of hair extensions that meet customer demands for quality and affordability.

In addition to technological advances in production methods, there has been an increase in demand for sustainable and eco-friendly hair extensions made from natural materials such as human remi hair or plant-based fibers like bamboo or cotton.

These materials offer a more ethical option for consumers who want to reduce their environmental impact while still enjoying beautiful natural hair extensions.

As consumer awareness continues to grow around sustainability issues related to fashion products like hair extensions, we can expect market growth for this trend to witness significant growth continue into the future.

Predictions for the Future of Hair Extension Manufacturing

The future of hair extension manufacturing is filled with promise significant growth and potential.

Manufacturers are continuously working to improve production processes, develop new materials, and expand into new markets to meet the ever-changing demands of their customers.

Technological advancements shaping the industry

1. Machine learning and artificial intelligence in production processes

Advances in machine learning and artificial intelligence are transforming the hair extension manufacturing industry, allowing manufacturers to produce higher-quality products faster and with greater precision.

Machine learning algorithms can be used to analyze customer data, such as hair type, texture, color, and style preferences, which helps manufacturers to predict consumer trends and develop better products to meet their needs.

2. Automation and robotics for increased efficiency and precision

Robotic technologies are being employed to automate production processes and reduce manual labor, which increases efficiency and improves product quality.

Automated machines can be programmed to perform precise tasks such as cutting, welding, and sewing with greater accuracy than human workers, resulting in faster production times and higher-quality products.

3. 3D printing and customized hair extensions for Synthetic hair extensions

Many hair extension manufacturers and key companies are focused on investing in research and development, as well growth factors such as sustainable production processes.

For example, 3D printing technology is being used to create custom-made hair extensions with unique textures and colors.

This technology allows for complete customization of the final product and faster lead times than traditional methods.

Manufacturers are also exploring the use of eco-friendly materials such as bamboo and biodegradable plastics to create products that are more sustainable.

In conclusion, the future of industry growth of hair extension manufacturing is quite promising.

With rising popularity of technological advancements in production processes and increased demand for sustainable solutions, manufacturers have an opportunity to capitalize on this growing global market.

Sustainable and eco-friendly practices

1. The rise of ethically sourced and traceable human hair extensions

The future of hair extension manufacturing is looking brighter than ever.

With advances in machine learning and artificial intelligence, manufacturers can now produce higher-quality products faster and with greater precision.

Automation and robotics are being used to automate production processes while 3D printing technology allows for complete customization of the final product.

Furthermore, ethically sourced human hair extensions are becoming increasingly popular as consumers become more aware of their environmental impacts when purchasing fashion products like hair extensions.

As a result, manufacturers have an opportunity to capitalize on this growing various extensions market by investing in research and development, sustainable production processes, eco-friendly materials such as bamboo or biodegradable plastics, and traceable human hair extensions.

2. Biodegradable materials for hair extensions

The use of biodegradable materials is a key factor gaining traction in the hair extension manufacturing industry as manufacturers strive to create more sustainable products.

These materials can be used to create both synthetic and human hair extensions that are eco-friendly and decompose quickly when exposed to the environment.

Biodegradable materials also provide a cost-effective option for those looking for an environmentally friendly solution.

3. Recycling and repurposing initiatives

Manufacturers are also looking to reduce their environmental footprint by investing in recycling and repurposing initiatives.

For example, some manufacturers are reusing hair clippings from salons and other sources to create new hair extensions, thus reducing the amount of waste generated.

Others are creating new products out of used synthetic fibers by melting them down and reforming them into something new.

These recycling and repurposing initiatives allow manufacturers to create eco-friendly products while saving money on raw materials, at the same time.

Innovation in hair extension application techniques

1. Improved installation methods for a more seamless and natural look

In recent years, manufacturers have been innovating in the area of hair extension application techniques.

They are striving for a more natural and seamless look by creating products that can be applied with minimal effort and fuss, such as clip-in extensions or adhesive tape systems.

These products require less time and skill to install than traditional methods, allowing for a faster and easier installation process.

2. Scalp micro pigmentation technology for a more realistic appearance

Scalp micro-pigmentation (SMP) is another emerging trend in hair extension application techniques.

This technique involves using tiny needles to implant pigment into the scalp, giving it a more natural appearance. This technique is ideal for those looking to achieve a more realistic and seamless look straight hair do.

2. Non-damaging application techniques

Manufacturers are also investing in techniques that reduce the amount of damage caused by traditional application methods.

For example, some companies are experimenting with laser technology to attach hair extensions without causing any heat or chemical damage.

These non-damaging application techniques can help increase the lifespan of a product while providing a more natural and comfortable experience for the wearer.

4. Virtual reality and augmented reality for virtual try-on

Augmented and virtual reality (AR/VR) technologies are also being used to create a more interactive try-on experience.

Manufacturers can now offer customers an immersive, 3D preview of their product before they purchase it, allowing them to get an accurate idea of how the extensions will look in real life.

This technology has potential applications in other areas as well, such as helping educational institutions provide virtual tutorials for hairstyling techniques or giving consumers a way to virtually customize products before purchasing them.

Implications for Hair Businesses, Salon Owners, and Online Retailers

Opportunities for growth and expansion

1. Meeting the increasing demand with advanced manufacturing techniques

As the demand for hair extensions grows, manufacturers must be prepared to meet it with advanced manufacturing techniques and innovative products.

This will involve investing in new technologies and production processes that can produce higher-quality products more efficiently and sustainably.

2. Adapting to changing consumer preferences and trends

Manufacturers must also stay up-to-date on the latest consumer and market trends to ensure they’re producing products that appeal to customers.

For example, as eco-friendly materials become increasingly popular, manufacturers must focus on creating products that use these materials as much as possible.

3. Targeting niche markets with customized hair extensions

In addition to mass-market products, manufacturers should also consider targeting niche markets in major regions with specialized and customized solutions.

For example, they could create extensions that are made from a specific type of hair or offer unique colors and styles for those looking for something more unique.

Enhanced customer experiences and satisfaction

1. Offering sustainable and ethically sourced products

The future of hair extension manufacturing is all about offering sustainable and ethically sourced products.

With the rise of conscious consumerism, customers are increasingly looking for companies that prioritize ethical sourcing and sustainability in their product offerings.

As a result, businesses must strive to ensure their supply chains are socially responsible and environmentally friendly if they want to remain competitive in this space.

Companies need to be able to provide evidence that their products have been responsibly produced without compromising on quality or affordability.

This means finding reliable suppliers who adhere to high standards for animal welfare and environmental protection while providing excellent customer service as well.

2. Providing personalized and tailored solutions

In addition to offering sustainable and ethically sourced products, businesses should also be providing personalized and tailored solutions.

Tailoring product offerings to meet customers’ specific needs is one key factors becoming increasingly important in the global hair extension market and manufacturing industry.

Customers expect more than just generic items – they want products that are specifically designed for their individual needs and preferences.

Businesses must be able to provide a wide range of options to choose from, so customers can find the perfect item for them without having to settle for something less than ideal.

Adapting to market changes and staying competitive

1. Investing in research and development for innovative products

As the industry evolves, manufacturers must invest in research and development to ensure they stay ahead of the competition.

They should be constantly looking for new technologies and techniques that can help them create innovative products that appeal to customers.

2. Investing in marketing and advertising strategies

Manufacturers also need to invest in effective marketing and advertising campaigns to promote their products and reach out to potential customers.

This could involve utilizing social media platforms, creating engaging content, investing in search engine optimization (SEO) tactics, and even attending trade shows.

3. Embracing digital marketing strategies for online visibility and customer acquisition

Manufacturers must also embrace digital marketing strategies to increase their online visibility and market share and reach a wider audience.

For instance, they should be investing in search engine marketing (SEM) tactics, creating online ads, optimizing their websites for mobile devices, and utilizing email marketing campaigns to drive traffic to their products.

These digital strategies can help them engage with customers more effectively and acquire new ones quickly.

Takeaways

The future of the hair extension market and manufacturing is all about investing in the right technology, staying up-to-date on consumer trends, targeting niche markets with specialized solutions, offering sustainable and ethically sourced products, providing personalized solutions, embracing digital marketing strategies, and investing in research and development.

By doing so, manufacturers can remain competitive with key players in this space and ensure their products are the best in the industry.

Ultimately, manufacturers need to be agile and open-minded about new opportunities if they want to stay ahead of the game.

By using these strategies, businesses can remain competitive and continue providing high-quality products for years to come.

Alvin Hair – Hair Extension Supplier

Alvin Hair is a leading hair extension company. We offer a wide range of products to meet the needs of our customers, from human virgin hair extensions to synthetic and clip-in hair extensions, fusion extensions, tape-in extensions all-in sets.

Our goal is to provide our clients with the highest quality real human hair extensions at an affordable price.

With over 10 years of experience in the industry, we are dedicated to providing exceptional customer service and meeting all of your hair extension needs.

Contact us today for more information on our extensive collection of products!