Human hair extensions have become an essential accessory for many people around the world, providing an easy and convenient way to achieve desired hairstyles.

However, the quality of these hair extensions can vary greatly depending on the manufacturing process.

As a hair extensions brand or salon owner, it is crucial to ensure that the products you offer meet highest quality standards to maintain customer satisfaction and brand reputation.

In this article, we'll discuss the importance of quality control in hair extension manufacturing, and how it can benefit your business.

We'll cover the manufacturing process of hair extensions, why quality control is crucial, how to implement quality control, and the benefits of doing so.

The Process of Hair Extension Manufacturing

The production process of hair extensions involves several phases that require careful attention to detail to ensure high-quality products for hair extension business.

Each step of the process has an important role to play in the final outcome, and quality control measures need to be in place for each step.

Here is an overview of the steps involved in hair extension manufacturing and the importance of quality control in each step:

Sorting and Preparing the Hair

The first step is to sort and prepare the hair, which involves separating the hair into different lengths, colors, and textures.

Quality control is an important factor in this step to ensure that the hair being used is of the highest quality, and to prevent any defective or low-quality hair from being used in the manufacturing process.

Washing and Conditioning

The next step is to wash and condition the hair to remove any dirt, oil, or other impurities.

Proper washing and conditioning are essential to maintain the hair's quality, so quality control measures need to be in place to ensure that the hair is thoroughly cleaned and conditioned.

Dyeing and Coloring

Dyeing and coloring is the process of adding color to the raw hair, either to match the natural hair color or to create a specific look.

Quality control measures need to be in place to ensure that the cuticle dyeing and coloring process is done correctly, without causing damage to the cuticles or the hair strands.

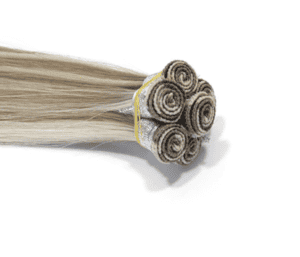

Wefting

Wefting is the process of sewing the hair onto a track or weft, which is what holds the hair together.

Quality control is crucial in this step to ensure that the wefting is done correctly and that the hair is securely attached to opposite ends of the weft.

Quality Inspection

The final step is to conduct a quality inspection of the hair extensions to ensure that they meet the required quality standards.

Quality inspection is essential to ensure that the hair extensions meet the requirements of hair extension businesses, salon owners, and hair extension brands and that they are of the highest quality for the end customers.

Why Quality Control in Hair Extension Manufacturing Business is Important?

Quality control is critical for hair extension manufacturing businesses to ensure that the products they offer meet high-quality standards consistently.

Quality control measures help in various ways, such as ensuring product consistency, meeting customer expectations, preventing potential issues and customer complaints, and maintaining brand reputation.

Here's a closer look at why quality control in hair extension manufacturing businesses is crucial:

A. Ensuring product consistency

Product consistency is vital to the success of any hair extension business. Customers expect to receive the same quality product every time they make a purchase.

By implementing quality control measures in each step of the production phases, hair extension manufacturers can ensure that the products they offer are consistent and meet customer expectations.

This includes using the same high-quality materials, such as premium hair extensions or remy hair, and ensuring that the synthetic hair used is of excellent quality.

With consistent quality products, hair extension businesses can build brand loyalty and customer satisfaction.

B. Meeting customer expectations

Customer expectations are high when it comes to hair extensions. They expect to receive a product that matches their natural hair color, texture, and overall appearance.

Quality control measures in each step of the production process, such as checking the hair cuticles, can help ensure that the hair extensions look and feel natural.

Meeting customer expectations is critical for the success of any hair business, and quality control can help achieve this.

C. Preventing potential issues and customer complaints

Preventing potential issues and customer complaints is crucial for hair extension businesses. Quality control measures can help identify and prevent issues before the product is released to customers.

For example, a quality control check can identify hair extensions with split ends or hair that doesn't match the natural hair color.

By addressing these issues before the product is released to customers, hair extension businesses can avoid customer complaints, returns, and negative feedback.

D. Maintaining brand reputation

Brand reputation is essential for hair extension businesses in the hair industry. Quality control measures can help maintain a brand's reputation by ensuring that the products they offer are of the highest quality.

By providing high-quality hair extensions consistently, hair extension businesses can build trust and loyalty with their customers, which is crucial for maintaining a company a strong brand reputation.

How to Implement Quality Control in Hair Extension Manufacturing

Implementing quality control measures is critical to the success of any hair extension manufacturing business.

Here are some essential steps to take when implementing quality control in hair extension manufacturing:

A. Identifying potential quality issues

The first step in implementing quality control measures is identifying potential quality issues. This includes identifying hair types that are prone to tangling or breakage and establishing protocols for addressing these issues.

Identifying potential quality issues upfront can help prevent them from becoming bigger problems in the future.

B. Setting hair quality standards

Setting hair quality standards is crucial to ensuring that hair extensions meet customer expectations. This includes establishing standards for hair texture, color, and overall appearance.

The goal is to create hair extensions that look and feel natural, so customers can achieve the look they desire. With a set of hair type quality standards, hair extension manufacturers can ensure that all the hair used in their products meets the same high-quality standards.

C. Creating quality control processes

Creating quality control processes involves establishing protocols for inspecting and testing hair extensions at various stages of production.

Quality control processes should include inspections for tangling, shedding hairs, and color consistency. Creating these processes will help ensure that every product meets the same high-quality standards.

D. Conducting regular inspections and testing

Conducting regular inspections and testing is crucial to ensuring that the hair extensions produced are of the highest quality. Inspections and testing should be done at every stage of production to identify any potential issues.

This includes inspecting the hair cuticles to ensure that the hair extensions look and feel natural.

By conducting regular inspections and testing, hair extension manufacturers can identify any potential quality issues before they become bigger problems, ensuring that future orders meet the same high-quality standards.

Implementing quality control measures is essential to producing hair extensions that are natural looking and meet customer expectations.

By identifying potential quality issues, setting hair quality standards, creating quality control processes, and conducting regular inspections and testing, hair extension manufacturers can produce high-quality products that meet the needs of their customers.

Benefits of Quality Control in Hair Extension Manufacturing

There are many benefits to implementing quality control measures in hair extension manufacturing.

Here are some of the most significant benefits:

A. Consistent product and high quality hair extensions

Implementing quality control measures ensures that every product is consistent and meets the same high standards. This includes using cuticle remy hair, which is the highest quality hair available.

By using high-quality hair and maintaining proper maintenance throughout production, hair extensions can withstand several washes without losing their natural look and feel.

Consistent product quality results in high-quality hair extensions that meet the needs of clients and business partners.

B. Increased customer satisfaction

Implementing quality control measures can increase customer satisfaction by producing hair extensions that look natural and are easy to maintain.

High-quality hair extensions are less likely to tangle, shed or look unnatural, which can lead to increased customer satisfaction.

Satisfied clients are more likely to recommend a hair extensions brand to others and become loyal clients, which can help increase the company' market share.

C. Positive impact on brand reputation

Maintaining high standards for hair extension production has a positive impact on brand reputation. Clients and business partners are more likely to recommend a brand that consistently delivers high-quality products.

Brand reputation is critical in the hair extension industry, where competition is high, and patrons have many options to choose from.

A positive reputation can also attract highly qualified employees and business associates, creating a more stable and successful business.

D. Reduced costs and waste

Implementing quality control measures can help reduce costs and waste in hair extension manufacturing.

By catching potential quality issues early on, manufacturers can avoid producing hair extensions that do not meet the standards and require rework. This reduces the costs associated with production and waste, which can help improve profitability.

Overall, implementing quality control measures in hair extension manufacturing can result in consistent, high-quality hair extensions, increased customer satisfaction, a positive impact on brand reputation, and reduced costs and waste.

Conclusion

In conclusion, quality control is an essential aspect of hair extension manufacturing.

By following the production process and implementing quality control measures, manufacturers can ensure that their hair extensions meet the highest standards of quality and consistency.

Quality control measures can also lead to increased customer satisfaction, positive brand reputation, and reduced costs and waste.

By using the right hair types and maintaining high standards throughout the production process, manufacturers can produce premium hair extensions that look natural and can withstand several washes.

By prioritizing quality control, hair extension businesses can build long-term relationships with clients and business partners, establish a positive reputation in the industry, and ultimately achieve greater success in the market.

Alvin Hair - Hair Extensions Supplier in China

If you're looking for a reliable and high-quality hair extensions supplier in China, consider Alvin Hair.

With years of experience in the industry, Alvin Hair offers a wide range of hair extensions, including cuticle remy and synthetic hair, to meet the needs of different clients and businesses.

Our hair extension products are made using the highest quality remy hair and are subject to rigorous quality control measures to ensure consistency and quality.

Contact us today to learn more about our products and services and how we can help you grow your hair extension business.