In the ever-evolving world of hair extension manufacturing, research and development (R&D) play a critical role in driving innovation, forecast period, inspiring growth, and producing superior products for customers.

As an industry that thrives on meeting diverse consumehttps://www.therobinreport.com/sustainable-alternatives-for-plastic-based-synthetic-hair demands, increasing demand, and staying ahead in a competitive global market, continuous investment in R&D is essential to develop cutting-edge technologies, sustainable practices, and new materials that cater to shifting preferences and needs.

In this article titled “The Role of Research & Development in Hair Extension Manufacturing: Innovations That Shape the Industry,” we will delve deep into the significance of R&D in the production sector, providing valuable insights for both manufacturers and consumers alike.

Throughout this article, readers can expect to gain an understanding of how R&D contributes to the advancements in hair extension manufacturing, with a focus on innovations that have transformed the global industry overview.

We will explore various aspects of R&D, major factors such as material sourcing, product development, and application techniques, highlighting their impact on the overall quality and performance of hair extensions.

Additionally, we will examine real-world examples statistical data and industry statistics that demonstrate the importance of R&D in this field, shedding light on the crucial role it plays for key companies in shaping the future of hair extension manufacturing.

By the end of this article, readers will have a comprehensive understanding of the vital role that research and development key players in the hair extension manufacturing industry and how it continues to foster progress and innovation that benefits both businesses and consumers alike.

Evolution of Hair Extensions Manufacturing

Over the past century, human hair extensions have developed dramatically, from a niche product to an increasingly popular beauty trend.

From early forms of human and animal hair weaves to synthetic and real-hair wigs and now modern tape-in, clip-in, sew-in, and many other methods of applying for extensions, there is a plethora of options to choose from.

This progress is largely due to the continuous investment in research and development by manufacturers, retailers, and beauty salons alike.

With each new innovation comes improved quality, increased durability, and more accessible prices for customers, resulting in a huge growing demand for hair extensions worldwide.

In terms of R&D specifically, manufacturers have been exploring and experimenting with different ways to improve production processes and the quality of synthetic or human hair extensions.

For example, advancements in technology have enabled manufacturers to create more secure bonding methods and materials that are more resistant to wear.

Such improvements have allowed for longer-lasting extensions with less maintenance required.

Additionally, manufacturers have dedicated significant resources to researching and sourcing higher-quality fibers that mimic the look and feel of natural hair.

As a result, modern-day synthetic hair extensions are virtually indistinguishable from human hair, offering customers realistic results without compromising on quality.

Moreover, advancements in product application techniques have enabled manufacturers to provide more customized and personalized solutions for their consumers. With more options available, customers can now achieve the exact look they want with ease.

These are just some of the ways in which R&D has revolutionized hair extension manufacturing, offering salon owners, businesses, retail stores and online retailers a serious market growth rate and a plethora of opportunities to grow.

Cutting-Edge Innovations in Hair Extensions Market

Advanced fiber technology

In the hair extensions and beauty industry group, research and development have been exploring new synthetic fibers to provide improved durability and a more realistic appearance.

Synthetic hair extension have long been used in the production of wigs and artificial hair-pieces, but they are now being adapted for use in extensions.

By using specially designed synthetic fibers, manufacturers can create extensions that look just like natural hair while providing superior longevity.

Additionally, these artificial materials allow for greater flexibility during product application processes, allowing customers to achieve their desired hairstyle with ease.

With this newfound versatility comes an ever-competitive landscape and increased demand from both businesses and consumers alike as they seek to capitalize on these innovations.

One such innovation is the integration of heat-resistant fibers into hair extensions, which provides customers with more options when it comes to styling their looks.

With these advanced materials, customers can use curling irons or other heated styling tools without fear of damaging their extensions.

In addition, this technology allows for longer-lasting results as the heat-resistant fibers are less likely to break down over time than traditional synthetic materials.

As a result of this innovation, businesses in the industry are now able to offer more customized solutions that meet customer needs while providing superior performance and longevity.

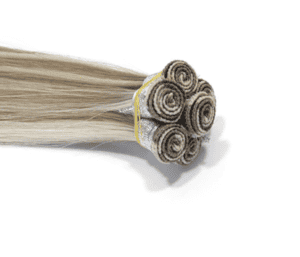

Enhanced bonding and attachment methods

Innovative bonding techniques play an important role in the hair extension industry’s growth, as they can offer stronger and longer-lasting connections than traditional methods.

Manufacturers have been exploring different ways to improve production processes and the quality of hair extensions by using advanced materials for secure attachment methods.

Manufacturers can create better products with higher durability and easier application by investing in research and development.

Through analysis of various bonding techniques, manufacturers have developed products that offer customers realistic results without compromising on quality or durability.

For those looking for a quick and easy solution to their hair extension needs, tape-in and microbead extensions offer an ideal solution.

With minimal damage to the natural hair follicles, these attachments provide a secure bond that can last up to several months with proper care.

Tape-in extensions are applied using adhesive tapes which are attached directly to the scalp, while microbeads use small metal beads that attach the extension strands securely without causing any strain or tension on the natural hair shaft.

Both methods of attachment allow for increased ease of use and minimal damage when compared with other conventional techniques such as fusion bonding or gluing.

Furthermore, tape-in and microbead extensions have become increasingly popular due to their affordability, convenience, low maintenance requirements, and long-lasting results.

Customization and color blending of hair extensions

The global hair and extension market has seen a revolution in recent years as manufacturers have utilized research and development to come up with more innovative solutions to meet customer needs.

One of the most impressive innovations is the advancement in color-matching technology, which allows for seamless integration with natural hair.

With this breakthrough, customers can now enjoy gorgeous hair extensions that blend perfectly into their existing hairstyle without any noticeable lines or discrepancies.

Manufacturers use complex algorithms and software to analyze the current hair color and produce a precise match for every extension strand.

This allows customers to achieve salon-quality results at home while avoiding expensive trips to professional stylists.

Moreover, the latest technology simplifies the process of tailoring products to meet specific customer requirements, thereby leading to online sales and an improved level of satisfaction among end users.

For individuals with sensitive skin, scalp-friendly adhesive options are essential for a comfortable hair extension application.

Traditional adhesives can cause irritation on the scalp due to their chemical components, but newer products have been developed that provide greater comfort and safety.

These new adhesives use natural ingredients such as plant oils which are gentle on the scalp and do not contain any harsh chemicals or irritants.

Also, they offer superior hold and durability compared to traditional synthetic adhesives, allowing for longer-lasting results without compromising on quality. With these innovative solutions, customers can now enjoy salon-quality looks while taking care of their scalps at the same time.

Sustainability and eco-friendly practices in the hair extensions manufacturing

As the market size for the hair extension market continues to expand, manufacturers are increasingly focusing on ethical production and sustainable practices.

One of the most significant changes is the use of ethically-sourced and recycled materials in the global hair extensions market.

By using high-quality human or animal hair that has been treated with care and respect, manufacturers can ensure their products meet customer expectations while also reducing environmental impacts.

Furthermore, these materials can be reused multiple times before they need to be replaced, thereby reducing waste and helping to conserve natural resources.

Companies are also exploring ways to repurpose post-consumer plastics into durable yet lightweight attachment systems for hair extensions that create a secure bond without causing any damage or discomfort on the scalp.

These innovations will help ensure that customers have access to safe, eco-friendly products while allowing companies to maintain an ethical standard of production at all times.

One of the most innovative solutions they have come up with is the development of biodegradable packaging options.

These eco-friendly alternatives help to minimize waste and preserve natural resources, while still providing customers with a safe and secure product delivery experience.

Biodegradable materials such as paper, starch-based plastics, and even seaweed can be used in hair extension packaging instead of traditional plastic or Styrofoam containers.

This helps to eliminate excess waste in landfills while also reducing carbon emissions from transportation.

Further, these biodegradable raw materials also are often more cost-effective than their non-biodegradable counterparts, making them an attractive option for companies seeking sustainable production methods without sacrificing quality or performance.

R&D Collaboration with Hair Professionals

In order to stay ahead of the curve in terms of hair extension technology, manufacturers are increasingly partnering up with stylists and salon owners to create innovative products.

These collaborations allow for a better understanding of customer needs, enabling manufacturers to develop more effective solutions that meet those demands.

Manufacturers can ensure their products have superior performance and meet industry standards for safety and quality by utilizing the expertise and experience of professional stylists.

Additionally, this partnership helps to bridge the gap between research & development (R&D) teams and the end user users, allowing both parties to benefit from each other’s knowledge.

This collaboration is essential for keeping up with new development trends in global hair extensions changing fashion trends, as well as improving existing technologies used in hair extension manufacturing processes.

It’s important for hair extension companies to establish feedback loops with their customers.

This allows them to collect insights and data on how users interact with their products, as well as the overall efficacy of those products in terms of performance and comfort.

These feedback loops can then be used by R&D teams to refine existing products or create entirely new ones that meet customer needs more effectively.

The Future of Human Hair Extensions Manufacturing

As the hair extension industry continues to grow and evolve, we are likely to see significant further growth opportunities and more innovation in the market share in terms of research & development (R&D) trends.

In particular, manufacturers are likely to focus on further improving their production processes while using production value and also striving for greater sustainability.

We can expect a continued emphasis on ethically-sourced and recycled materials as well as biodegradable packaging options that reduce waste and conserve natural resources.

Additionally, R&D teams will be collaborating with professional stylists and salon owners in order to create innovative products that meet customer needs more effectively.

Through these collaborations, manufacturers will be able to bridge the gap between their R&D teams and end users while staying up-to-date with new trends in hair fashion.

Ultimately, this could lead to an even better experience for customers when it comes to purchasing hair extensions from reputable companies.

Implications for Hair Businesses, Salon Owners, and Online Retailers

In a competitive market, embracing research and development (R&D) can be the key to differentiating your business from the competition.

By investing in R&D initiatives, businesses can develop more innovative products that meet customer needs more effectively.

This could include creating new technologies for hair extension manufacturing processes or experimenting with biodegradable packaging options that reduce waste and conserve natural resources.

Further, companies should also focus on establishing feedback loops with their customers in order to collect insights and data on how users interact with their products.

With this information, they can refine existing products or create entirely new ones that better suit customer needs. Embracing R&D will help businesses stay ahead of trends while providing customers with a superior product experience – both of which are essential for success in today’s competitive marketplace.

Incorporating innovative hair extensions into product offerings can be a great way to stand out from the competition and increase customer loyalty.

Businesses should start by focusing on creating unique product offerings that are tailored to their target audience.

This could include sourcing ethically-sourced, recycled materials for production or experimenting with different textures and colors that offer customers more variety.

It’s also important for businesses to utilize feedback loops with their customers in order to gather insights and data on how users interact with their products. This information can then be used to refine existing products or create entirely new ones that better meet customer needs.

Additionally, businesses should consider partnering with professional stylists and salon owners in their market participants in order to gain insight into emerging trends in hair care fashion.

Through these collaborations, companies can ensure that they are staying up-to-date with the latest developments in the industry while gaining valuable knowledge and experience from professionals who have an intimate understanding of customer needs.

Finally, businesses should strive for greater efficiency and sustainability throughout their production processes.

This could include optimizing manufacturing techniques to reduce waste and conserve resources as well as implementing biodegradable packaging options that reduce environmental impact.

By incorporating these growth strategies into their product offerings, businesses can gain a competitive edge while providing customers with superior-quality hair extensions that meet all of their needs.

Takeaways

It is clear that research and development (R&D) plays a pivotal role in hair extension manufacturing.

Through R&D initiatives and growth factors, businesses can develop innovative products tailored to customer needs while staying up-to-date with the latest fashion trends in hair extensions industry.

Also, companies should strive for greater efficiency and sustainability throughout their production processes by optimizing techniques that reduce waste and conserve natural resources.

By investing in R&D initiatives such as these, businesses will be able to gain an edge over competitors while providing customers with superior product experiences – both of which are essential for success in today’s competitive marketplace.