Touring a hair extension factory can be an invaluable experience for those looking to learn more about the production process behind high-quality extensions.

Understanding how different materials, tools, and processes are used to create quality hair products is essential for anyone in the hair industry.

Touring a hair extension factory provides an opportunity to gain firsthand knowledge of these important aspects of manufacturing, as well as insights into potential areas of improvement or innovation.

Additionally, touring a hair extension factory allows professionals and business owners alike to connect with manufacturers who may become valuable partners in the future.

By taking a tour of a factory that produces high-quality hair extensions, you'll gain valuable insight into purchasing hair extensions and how your own product line could benefit from their expertise and resources.

This blog post will focus on providing you with the benefits of touring a hair extension factory and what to look for when doing so.

Advantages of Touring the Hair Extension Factory

There are many benefits of touring the hair extension factory of your choice. From evaluating the quality of service they provide to the discussion of sales and pricing, we'll dive into more details below:

Getting The First Impression: Hair Industry Factory Infrastructure

When touring a hair extension factory, it’s important to look for signs of a clean and well-organized workspace.

A tidy environment indicates that the company takes pride in its craftsmanship and is committed to delivering quality products. It also shows that they have systems in place to ensure production runs smoothly and efficiently.

A chaotic workspace can lead to potential safety hazards as well as lower product standards due to a lack of organization and attention to detail.

Additionally, a dirty or cluttered space may indicate poor sanitation practices which could potentially cause damage or contamination of products if not properly addressed.

Taking note of the overall hair texture and appearance when touring a hair extension factory will give you insight into the level of care taken by its staff during production.

Safety and hygiene standards are of utmost importance when touring a hair extension factory. It's important to look for signs that the facility has proper safety measures in place, such as fire extinguishers and emergency exits.

Plus, it's essential to observe how the staff handles materials to ensure they follow proper sanitation practices.

Examination of the quality control procedures in place for natural hair

Quality control is an essential process in ensuring the production of consistent and superior products at a hair extension factory. It involves assessing the quality of materials used and the production processes to ensure that each product meets quality standards.

When touring a hair extension factory, it’s important to assess the reliability of their quality control processes. This includes looking at the testing methods used on different materials, both natural and synthetic, to ensure they meet the desired standards.

It also entails examining the quality of their machines and tools to make sure that all parts are running properly and in good condition.

Look for evidence of regular inspections or certifications from reputable third-party organizations that can back up the factory’s quality control process.

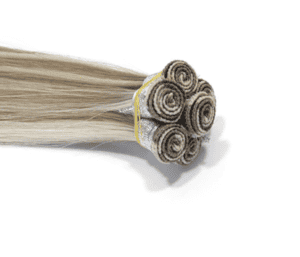

Sourcing and Selection of Human Hair Materials

When it comes to sourcing the best quality hair for their extensions, many factories will go above and beyond to ensure they are selecting only the finest materials.

Hair extension factories often source human hair from a variety of sources, such as local salons wholesale hair vendors, or international vendors.

The selection process is critical in ensuring that the final product meets a certain standard of quality. Many factories have strict criteria when it comes to their hair vendors choosing which hairs make the cut and which don’t.

They may look at factors such as texture, color, length, thickness, and more before deciding whether or not to accept them into their inventory.

In some cases, hair business owners may even visit potential hair suppliers themselves in order to observe first-hand how they handle their material and its overall quality prior to making any purchases.

This allows them to select only those hairs that meet their exacting standards for use in production.

Manufacturing Techniques

When touring a hair extension factory, it is important to explore the manufacturing processes involved.

The production of quality hair extensions requires advanced techniques and specialized machinery in order to ensure that each product meets the highest standards.

As a business owner, it is also your responsibility to know the process of sourcing hair extensions of the factory. You have to ensure you are getting the highest quality hair may it be remy hair, synthetic hair, and more.

By closely examining the various steps taken during production, potential customers can get an idea of how much care and attention goes into every item produced by the factory.

From sourcing raw hair extension materials to inspecting finished products for quality control, there are many factors that need to be considered when assessing a manufacturer's capabilities.

By taking a closer look at these processes, customers can gain valuable insight into what sets one factory apart from another in terms of their commitment to excellence and customer satisfaction.

It's also important to assess the reliability of their machinery and technology. Modern hair extension factories utilize advanced machinery and technology in order to produce high-quality products.

This includes state-of-the-art machines, such as hydraulic presses, computerized cutting and weaving machines, digital color analyzers, and other specialized tools.

By assessing the reliability of these machines, customers can get a better idea of how quickly and efficiently the factory is able to produce their extensions. The staff’s level of expertise should also be taken into account when evaluating production capabilities.

Customization and Product Range of Hair Extensions

When touring a hair extension factory or buying hair out, it is also beneficial to understand the range of products available.

From clip-in extensions to tape-in hair extensions, weaves, wigs, and more, factories can produce a variety of different styles and hair textures that can be customized to meet the specific needs of customers.

It is important for potential customers to be aware of the range of products on offer in order to make an informed decision.

By touring a hair extension factory and closely examining all aspects of its operations, customers can gain valuable insight into the quality of the extensions they produce and the level of service they provide.

From inspecting materials to evaluating production capabilities, it is important for customers to do their due diligence when selecting a factory for their own hair extension needs.

With the right information, they can rest assured that their investment will result in beautiful, high-quality extensions that will last for years to come.

Ethical and Sustainable Practices

When touring a hair extension factory, it is important to consider not only the quality of the products they produce but also their ethical and sustainable practices.

Ethical sourcing and labor practices are essential for ensuring that customers receive high-quality, ethically produced extensions that meet all safety standards.

By taking the time to research a potential supplier, customers can rest assured that their investment will be supporting businesses with responsible production processes.

When evaluating the commitment of a hair extension factory to sustainability, it is important to consider its overall approach to production. This includes looking at the materials they use and how these are sourced, as well as reviewing any processes that seek to reduce waste and conserve resources.

For example, factories may utilize eco-friendly dyes and materials, invest in renewable energy sources, or take other steps to reduce their environmental footprint.

By carefully assessing the policies of a potential supplier before committing to doing business with them, customers can ensure that they are supporting responsible and sustainable practices.

Arrangement of Competitive Pricing of Hair Extensions and Delivery Timelines

When visiting a hair extension factory, it is crucial for prospective customers to talk about pricing strategies that can compete in the market.

Factory owners should be willing to negotiate prices in order to remain competitive in the market. It is also crucial for customers to get an overview of the delivery timelines offered by the factory – this will help them ensure that they can reliably meet their own customer’s requirements in a timely manner.

Analysis of the factory's efficiency in meeting delivery timelines should be done in order to understand the potential delays that may be encountered during the production phase.

This is especially important for customers who are focused on timely delivery and need assurance that they can consistently meet their promised timelines.

The importance of balancing cost-effectiveness and quality control is also paramount when selecting a hair extension factory.

After-Sales Support and Collaboration

When selecting a hair extension factory, it is important to consider not just the quality of its products and services but also its commitment to collaboration.

A good partnership between the customer and supplier can help both parties achieve success through mutual growth opportunities.

For example, by working together on new product development, customers can leverage the expertise and resources of a factory to create unique extensions that meet their specific needs.

The factory's experience in production techniques can be beneficial for developing innovative solutions that will make customers stand out from the crowd.

In addition, factories should offer after-sales support so that customers have access to technical assistance when needed.

This could include troubleshooting tips or advice on the proper maintenance over time for optimal performance and longevity. By providing ongoing support, suppliers demonstrate an ongoing commitment to helping customers succeed in their businesses.

Finally, it is important for suppliers and customers alike to look at ways they can collaborate with each other as partners in order to build relationships based on trust and respect for mutual growth opportunities.

Conclusion

Visiting a hair extension factory is an important part of the process for customers who are looking to purchase high-quality, ethically produced extensions.

By taking the time to evaluate potential suppliers and their commitment to sustainable production practices, customers can ensure that they are investing in reliable partners with responsible processes.

Additionally, it's essential for customers to assess affordable price strategies and delivery timelines before making any commitments.

Finally, building strong relationships based on mutual trust and respect through collaboration will help both parties find success in their businesses.

Alvin Hair - Professional Hair Extension Factory with Years of Experience

At Alvin Hair, we understand that selecting the right hair extension factory is essential for clients who are looking to purchase high-quality and ethically produced virgin hair extensions.

With decades of experience in the industry, our services have been high demand and our team can provide you with reliable advice and support throughout the process.

We also offer competitive prices, efficient delivery timelines, and after-sales support to ensure that our customers have access to the best possible solutions for their needs.

With a commitment to sustainable production practices and collaboration between our teams, Alvin Hair is dedicated to helping you find success in your business. Contact us today to learn more!