Introduction

The hair extensions industry is highly competitive, and businesses need to carefully consider strategic aspects of their operations management to remain successful.

Outsourcing has become an important aspect of this decision-making process, allowing companies to reduce production costs, access specialized expertise, and scale production quickly. However, the outsourcing decision also comes with its own set of challenges and risks.

In this article, we will explore the pros and cons of outsourcing hair extension production to a factory, and provide guidance on factors to consider and best practices for making this decision.

By the end of this article, hair businesses, salon owners external suppliers, and online retailers will have a better outsourcing decision while understanding the strategic aspects of outsourcing and how it can have a positive impact on their operations management.

Pros of outsourcing hair extensions production to a factory

Cost reduction

One of the most significant benefits of outsourcing hair extension production to a factory is cost reduction.

Outsourcing can allow companies to take advantage of economies of scale and lower labor costs in countries such as China, where many factories are located.

By outsourcing, hair extension business owners can save on expenses related to hiring and training workers, investing in equipment and machinery, and maintaining production facilities.

These savings can be passed on to customers, and increase profits by allowing businesses to offer more competitive prices and increase profit margins.

Access to specialized expertise

Access to specialized expertise: Outsourcing also allows hair extension suppliers to access specialized expertise that may not be available in-house.

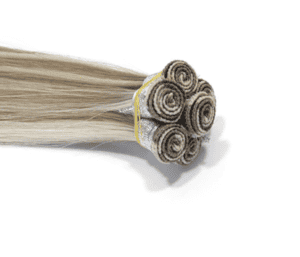

Factories often have specialized equipment, technology, and processes that can improve the quality and efficiency of hair extension production.

For example, a factory may have a high-tech hair-weaving machine that can produce a more natural-looking hair extension.

Outsourcing can also provide a company with access to expert knowledge in areas such as quality control, logistics management, and compliance, which can improve the overall performance of the company and supply and value chain.

Ability to scale production quickly

Another advantage of outsourcing is the ability to scale production quickly to meet changing customer demands.

Factories can often produce larger quantities of hair extensions at a faster pace than in-house production, allowing suppliers to take advantage of new opportunities and respond to fluctuations in demand.

This can be especially an important factor during peak season or for hair extension suppliers experiencing the first stage of rapid growth.

Reduction in time-to-market

Outsourcing hair extension production to a factory can also lead to a reduction in time-to-market or the time it takes for a product to reach the market.

This is because factories often have more experience and resources to manage production schedules and minimize delays.

For example, a factory may have multiple production lines, allowing them to produce different hair extensions simultaneously, reducing the overall production cost and saving some time.

Increased flexibility in manufacturing operations

Outsourcing also provides hair extension suppliers with increased flexibility in their manufacturing operations.

Suppliers can focus on their core competencies, such as marketing and sales while outsourcing production to a factory. This can allow businesses to be more responsive to changes in the market and to develop new products more quickly.

Outsourcing can also provide significant improvement for businesses with more options for customization, as factories often have the expertise and the latest technology to create unique hair extensions tailored to customer needs.

Lower risk of production-related problems

Finally, outsourcing hair extension production to a factory can lower the risk of production-related problems.

Factories often have rigorous quality control processes to ensure that hair extensions meet certain standards.

This can help to reduce the likelihood of defects, delays, or other issues that could impact customer satisfaction.

In addition, offshore outsourcing can also mitigate risks related to labor disputes, regulatory compliance, and supply chain disruptions.

Cons of outsourcing hair extensions production to a factory

Quality control issues

One of the major drawbacks of outsourcing hair extension production to a factory is quality control issues.

When working with foreign companies, it can be challenging to ensure that they meet the same quality standards as in-house production.

Poor-quality hair extensions can result in customer complaints, returns, and negative reviews, which can harm the hair extension supplier's reputation.

Additionally, it can be challenging to monitor quality control when dealing with a large volume of hair extensions, which can lead to an increased risk of defects.

It is crucial to establish a positive relationship with the factory to ensure that quality control processes are in place and being followed.

One way to mitigate quality control issues is to employ a standardized measurement approach, such as the measurement model the average variance extracted (AVE), to monitor the quality of the hair extensions.

Communication barriers

Outsourcing hair extensions production to a factory can also result in communication barriers, particularly when working with a factory in a foreign country.

Language barriers, time zone differences, and cultural differences can all contribute to communication challenges that can impact strategic performance and operational efficiency.

Miscommunication can lead to delays, incorrect orders, and misunderstandings, which can all harm the relationship between the hair extension supplier and the factory.

Effective communication is essential to mitigate these risks, and it may be necessary to invest in translation services or other tools to facilitate communication.

Limited control over the production business process

Outsourcing hair extension production to a factory can also result in limited control over the production business process.

Hair extension suppliers may have limited visibility into the factory's operations, which can make it difficult to monitor performance or identify areas for improvement.

Additionally, hair extension suppliers may not have control over the production schedule, which can impact their ability to meet customer demand or respond to changes in the market.

To address these challenges, hair extension suppliers should establish clear communication channels with the factory and regularly review performance metrics to identify areas for improvement.

Intellectual property concerns

Another concern when outsourcing hair extensions production to a factory is intellectual property concerns. This includes protecting trademarks, patents, and other proprietary information.

Hair extension suppliers must ensure that their intellectual property is protected, especially when working with foreign companies that may have different laws and regulations.

Failing to protect intellectual property can result in legal issues and a loss of profits.

Difficulty in finding a reliable factory

Finally, one of the major cons of outsourcing hair extensions production to a factory is the difficulty in finding a reliable factory.

There are many factors to consider when selecting a factory, including quality control, pricing, lead times, and capacity.

It can be challenging to find a factory that meets all of these requirements, and hair extension suppliers may need to invest significant time and resources in the selection process.

Additionally, working with a new factory can result in a learning curve that impacts operational productivity and strategic performance.

To mitigate this risk, hair extension suppliers should conduct thorough due diligence and establish clear communication with the factory to ensure that expectations are aligned.

Factors to consider when outsourcing hair extensions production to a factory

Quality standards and production processes

One of the most critical factors to consider when outsourcing hair extensions production to a factory is quality standards and production processes.

It is essential to ensure that the factory adheres to the same quality standards as the hair extension supplier and uses appropriate production processes.

This can help to maintain consistency in the final product and avoid potential quality control issues.

Hair extension suppliers should consider visiting the factory in person to assess the quality of the production process and hair extensions.

Factory location and reputation

Another important factor to consider when outsourcing hair extensions production is the factory location and reputation.

The factory's location can impact shipping costs and lead times, while the reputation can provide valuable information on their ability to deliver quality hair extensions.

Hair extension suppliers should look for factories with a track record of producing high-quality hair extensions, as well as those that are located in areas with a strong manufacturing industry.

Communication channels and language barriers

Effective communication is critical when outsourcing hair extensions production to a factory.

It is essential to establish clear communication channels and ensure that there are no language barriers that could lead to misunderstandings.

Hair extension suppliers should consider using translation services or hiring local staff who are fluent in both languages to facilitate communication.

Intellectual property protection and confidentiality

Protecting intellectual property is crucial when outsourcing hair extensions production to a factory.

Hair extension suppliers should ensure that the factory has appropriate measures in place to protect their intellectual property and maintain confidentiality. This includes non-disclosure agreements and other legal protections that can prevent the factory from sharing proprietary information with competitors.

Production capacity and lead times services sector

Hair extension suppliers should also consider the production capacity and lead times of the factory when deciding whether to outsource hair extensions production.

Larger factories may be better suited for high-volume production, while smaller or medium-sized companies may offer more personalized service.

Additionally, lead times can impact the ability to meet customer demand and respond to changes in the market.

Cost and pricing considerations

Finally, cost and pricing considerations are critical when outsourcing hair extensions production.

While outsourcing can result in reduced costs, hair extension suppliers should ensure that they are not sacrificing quality for price.

It is essential to negotiate fair pricing that reflects the quality of the hair extensions and the services provided by the factory.

Hair extension suppliers should also consider the development potential of the factory, as this can impact long-term costs and profitability.

Conclusion

In conclusion, outsourcing hair extensions production to a factory can provide many benefits to hair extension suppliers, including cost reduction, access to specialized expertise, and increased flexibility in manufacturing operations.

However, it is also essential to consider the potential drawbacks, such as quality control issues, communication barriers, and limited control over the production business process.

By carefully considering the various factors involved, such as quality standards, factory location and reputation, communication channels, intellectual property protection, production capacity, and cost and pricing considerations, hair extension suppliers can make an informed decision on whether outsourcing is right for them.

Alvin Hair - Your Trusted Hair Extensions Supplier

At Alvin Hair, we take pride in being your trusted hair extensions supplier.

With years of experience in the industry, we have established ourselves as a leading provider of high-quality hair extensions to salons, hair extension brands, and wholesalers worldwide.

Our commitment to quality and customer satisfaction is unmatched, and we are constantly improving our products and services to meet your needs.

Whether you are looking to outsource your hair extension production or simply need a reliable supplier, Alvin Hair is here to help.

Contact us today to learn more about how we can support your business and take it to the next level.